Conductive Ceramics: Embedding Electronics in Everyday Ceramic Objects

A method for integrating conductive traces into ceramic objects using silver-based glaze compatible with traditional firing processes | CHI 2025

Project Overview

Conductive Ceramics presents a method for integrating electronic functionality directly into ceramic objects using a silver-based conductive glaze. Rather than treating electronics and ceramics as separate systems requiring assembly, this approach embeds conductive traces within the ceramic fabrication process itself. The technique preserves the aesthetic and functional qualities of traditional pottery while enabling interactive, sensing, and heating capabilities.

Material Development

The conductive glaze consists of three main components combined in specific ratios:

- 97% silver powder (1μm particles) for electrical conductivity

- 3% glass former powder to create adhesion and durability during firing

- Xanthan gum solution (1% by weight in water) as a binder and suspension agent

This formulation was developed to work within standard pottery firing temperatures and to be compatible with common ceramic bodies, making it accessible to practitioners working in community studios without specialized equipment.

Fabrication Process

Creating conductive traces in ceramic objects follows a four-step workflow that integrates with traditional pottery techniques:

- Preparation: Measure ingredients by weight. Prepare xanthan gum solution and combine silver powder with glass former powder.

- Mixing: Combine powder mixture with xanthan gum solution at a 1:1 ratio by weight. Mix until achieving an evenly-dispersed, slip-like consistency suitable for application.

- Application: Apply silver glaze in thin layers to a fully mature (bisque-fired) ceramic body. Application methods include hand painting for freeform designs, digitally-cut vinyl resist for precise patterns, or automotive tape masks for clean edges.

- Firing: Fire to Cone 08 (1700°F) to sinter the silver particles and melt the glass former, creating a conductive, durable surface. Optionally burnish with a smooth tool to enhance conductivity, or apply additional low-fire clear glaze and fire again for protection.

Design Benefits

This approach offers three key advantages over alternative methods for integrating electronics with ceramics:

- Preserves functionality and durability: The conductive traces withstand the same handling, washing, and use as conventional ceramic glazes, maintaining structural integrity over time.

- Aligns with established workflows: The process uses familiar pottery techniques and standard kiln firing schedules, requiring no specialized equipment beyond the glaze materials themselves.

- Remains accessible: Practitioners in community studios can use this method without access to industrial facilities, expanding who can create electronically-enhanced ceramic objects.

Application Examples

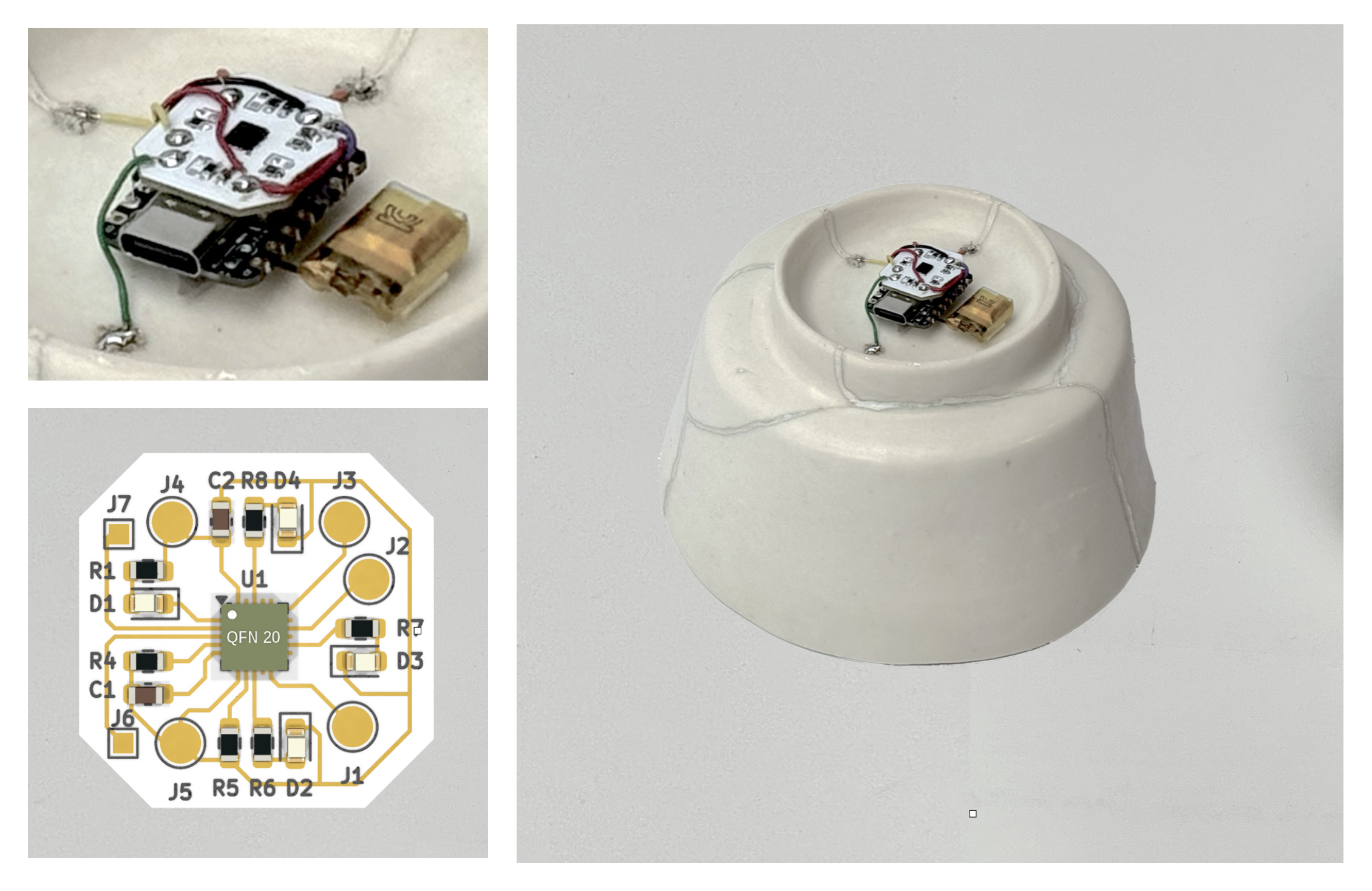

Kintsugi Musical Controller: The conductive glaze is used in a kintsugi-style repair to create touch-sensitive triggers for musical interaction using capacitive sensing. The repaired cracks become functional electronic interfaces, merging the aesthetic of visible repair with interactive capability.

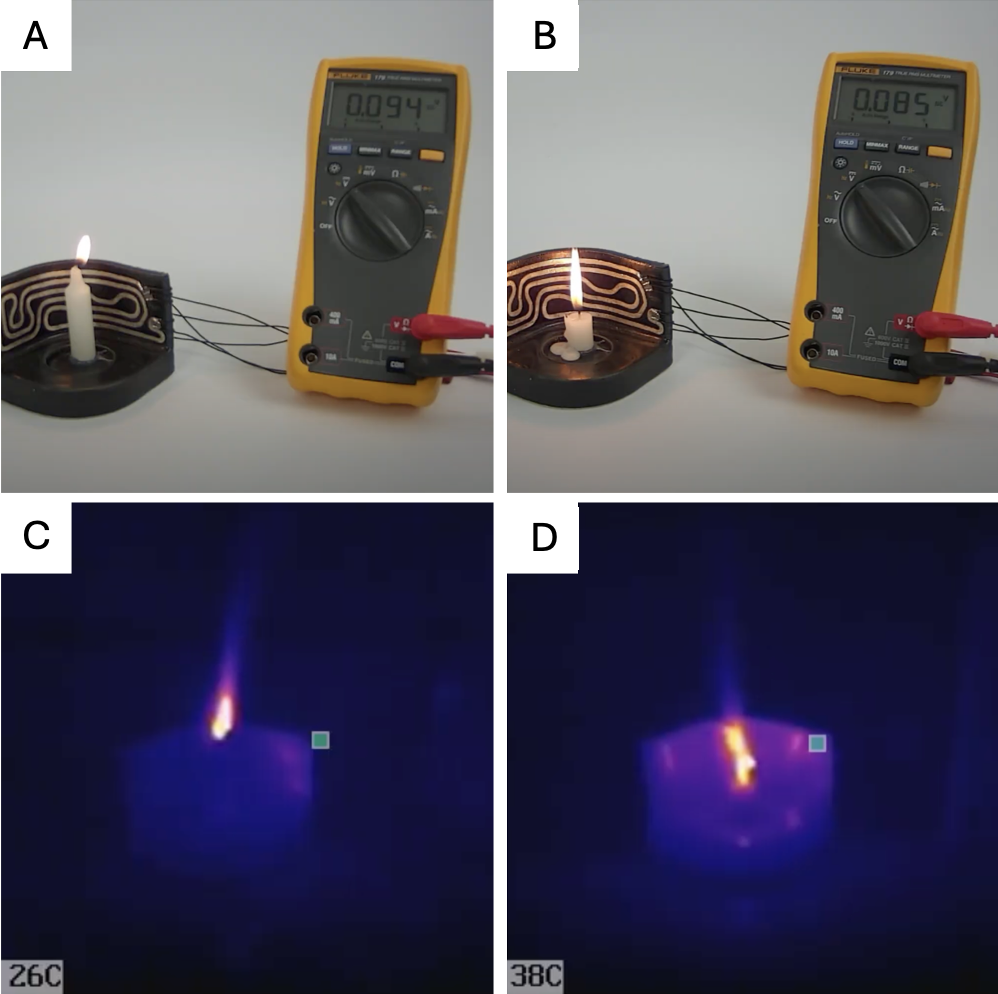

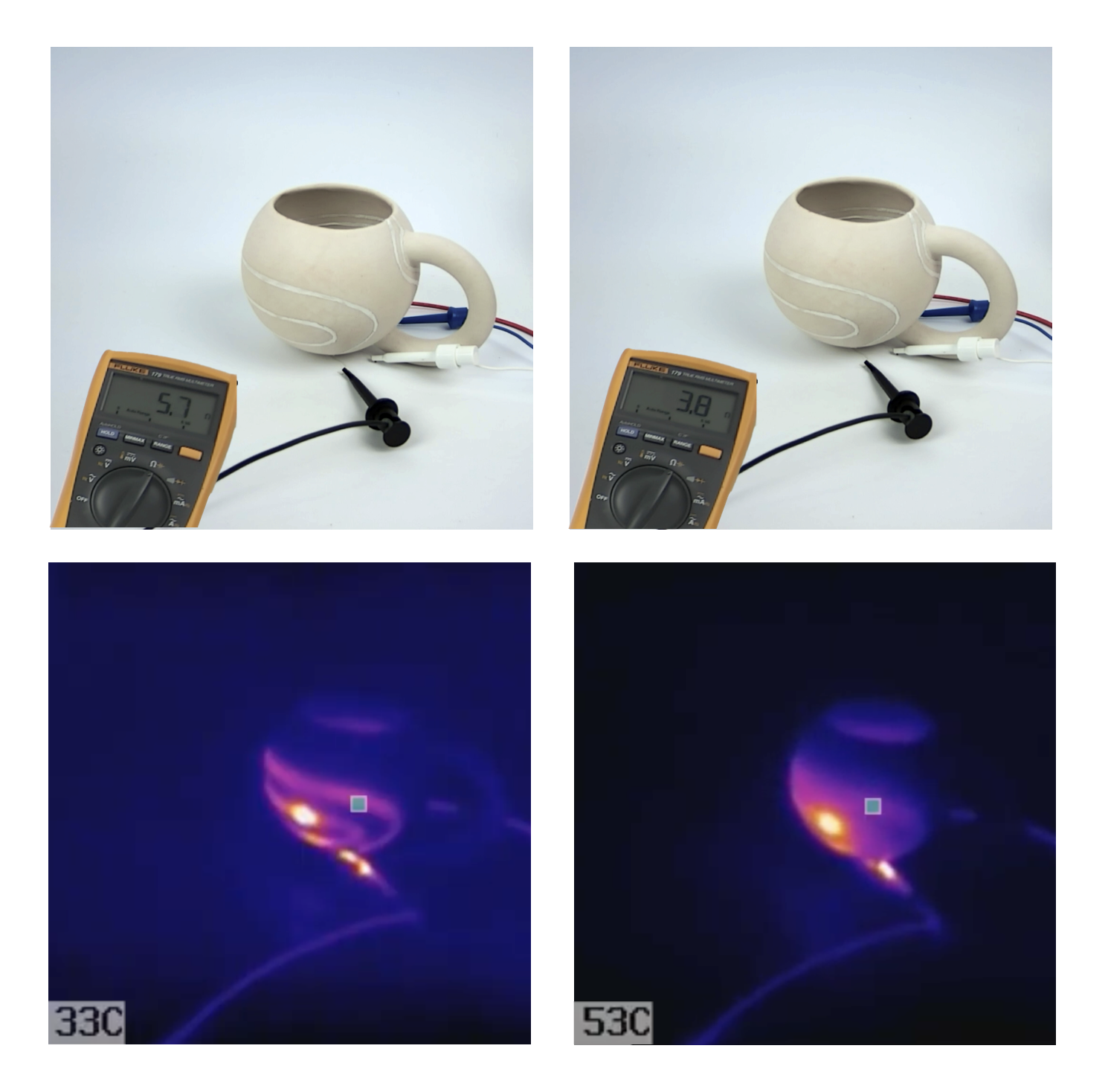

Smart Ceramic Cup: Combining resistive heating and temperature sensing, this cup can heat itself and monitor its own temperature. The conductive traces serve dual purposes—carrying current for heating while also functioning as resistance-based temperature sensors through changes in conductivity.

Interactive Marble Machine Sculpture: Conductive traces painted with silver glaze illuminate LEDs as a metal marble connects the circuit while rolling down the track. The sculpture demonstrates how conductive ceramics can create dynamic, kinetic electronic art pieces.

Design Space

Conductive Ceramics opens a design space at the intersection of traditional craft and electronic functionality. By treating conductivity as a glaze property rather than a separate system, the method enables:

- Electronics that share the thermal, mechanical, and aesthetic properties of the ceramic body

- Circuits that are visible design elements rather than hidden components

- Objects where interaction and decoration are unified through the same material

This approach suggests new possibilities for everyday objects that sense, respond, and communicate while maintaining the tactile and visual qualities valued in handmade ceramics.

For more information, please read the paper or see the poster.